Two additive manufacturing techniques allow ProtoCAM to produce metal parts and prototypes: metal casting and direct metal laser sintering (DMLS). Each technique has its own best use cases, and can deliver a wide variety of results to meet every need when it comes to speed, durability, aesthetics, and budget.

About Metal Casting

Metal casting techniques at ProtoCAM include investment casting, sand casting, and plaster mold casting. These methods are far faster than conventional tooling and machining methods. This process is ideal for the rapid creation of short-run metal parts with a high degree of accuracy, durability, and quality.

Why Choose Metal Casting

Investment casting, also called lost wax casting, uses a 3D-printed wax pattern, a cast wax pattern, or an SLA QuickCast pattern. Parts can be created from steel, Everdur (bronze mix), aluminum, and ferrous and non-ferrous metals. Choose investment casting for:

- Fast creation of multiple metal parts without the expense of conventional tooling.

- Low-quantity (1-50) requirements.

- Rapid prototype turnaround, with metal parts being created in 2-4 weeks or less, depending on method and foundry capacity.

- Highly accurate, high-quality projects; parts require little post-casting machining and processing to remove flashing and surface preparation, and ProtoCAM’s proprietary investment casting methods allow for walls as thin as .012 inches.

Sand casting, also called sand-molded casting, is a metal casting process that uses sand as the tooling material. Mold sands that are used in sand casting include silica sand, olivine sand, chromite sand, zircon sand, and chamotte sand. Choose sand casting for:

- Smaller-budget projects; sand casting is the least expensive way to create short-run metal-cast prototypes and products.

- Rapid prototype turnaround, with metal parts being created in 2-4 weeks or less, depending on foundry capacity.

Plaster mold casting is extremely similar to sand casting. The key difference is that the molding material is plaster of paris, rather than sand. Choose plaster mold casting for:

- Projects that require a higher level of surface finish and accuracy than sand casting can achieve.

- Rapid prototype turnaround, with metal parts being created in 2-4 weeks or less, depending on foundry capacity.

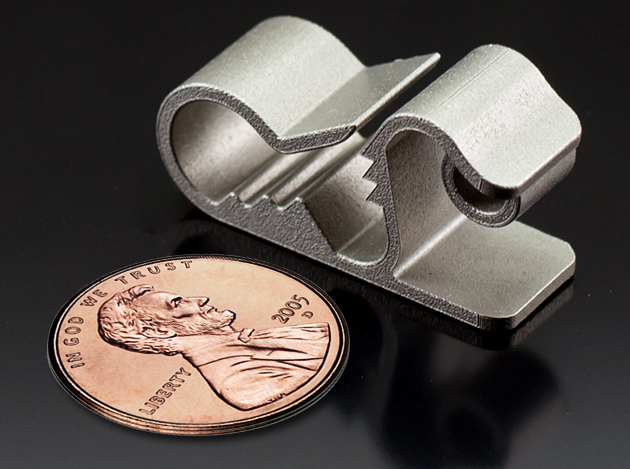

About Direct Metal Laser Sintering

Direct metal laser sintering (DMLS) is an ideal rapid prototyping solution for customers that need high-quality 3D metal parts or metal prototypes quickly. Although DMLS typically costs more than other rapid prototyping techniques, no special tooling is required, allowing for turnaround times of 2-4 weeks. This process is typically used for highly complex, intricate parts that would be difficult or impossible to produce with traditional methods.

In DMLS, 3D metal parts are created by fusing, or sintering, powdered metals with the heat from an infrared laser beam. Similar to Selective Laser Sintering (SLS), metal layers are repeatedly laser sintered, creating the desired three-dimensional piece based on a 3D CAD model or STL file. There are multiple metal materials available for DMLS, including aluminum, cobalt chrome, maraging steel, nickel alloy 625, nickel alloy 718, stainless steel, and titanium.

Direct Metal Laser Sintering in Action

Why Choose Direct Metal Laser Sintering

Homogenous Materials

DMLS metal 3D printing uses homogenous materials, minimizing potential complications.

Easily finished

Parts produced using DMLS metal 3D printing can easily be machined, EDM processed, polished, etched, textured and more.

Variety of material options

Parts can be produced using a variety of material types.

Typical Metal Prototyping Use Cases

| Small-batch manufacturing | Simulated investment-cast parts | Temperature-resistant pieces |

| Machinable parts | Functional prototypes |